How We Safely Prepare and Install Stone Benchtops in New Zealand

How We Safely Prepare and Install Stone Benchtops in New Zealand

We’ve seen studies that detail the risks of fabricating engineered stone. The facts are straightforward and well documented. Essentially, science shows that engineered stone can contain crystalline silica. This is not unlike many other everyday products such as glass, bricks, ceramics, and pottery. The precise amount varies widely depending on the stone type. Granite as an example may contain anywhere from twenty to sixty per cent. It is the respirable crystalline silica (RCS) released into the air which can cause silicosis. Silicosis is an occupational disease in the lungs brought on by exposure to RCS.

The Real Issue

Unfortunately, some are misrepresenting the issue. They claim that using stone is unsafe and just plain wrong. What they’re missing, however, is that the problem is not with the material, but with a failure to follow proper safety guidelines. As individuals, and a company, we take the safety and wellbeing of our staff very seriously. As such, we work in strict adherence to a comprehensive safety plan to keep everyone in the fabrication process from harm.

Industry Guidelines Are in Place

A “Good Practice Guide” has been put into place as a safeguard by NZESAG. The NZ Engineered Stone Advisory Group was founded in 2019 by leading importers/suppliers of engineered stone/quartz surfaces. This was in direct response to the occupational risks for those who manufacture these products. This has been peer-reviewed by technical experts including Occupational Hygienists and Occupational Physicians.

How We Are Moving Forward Safely

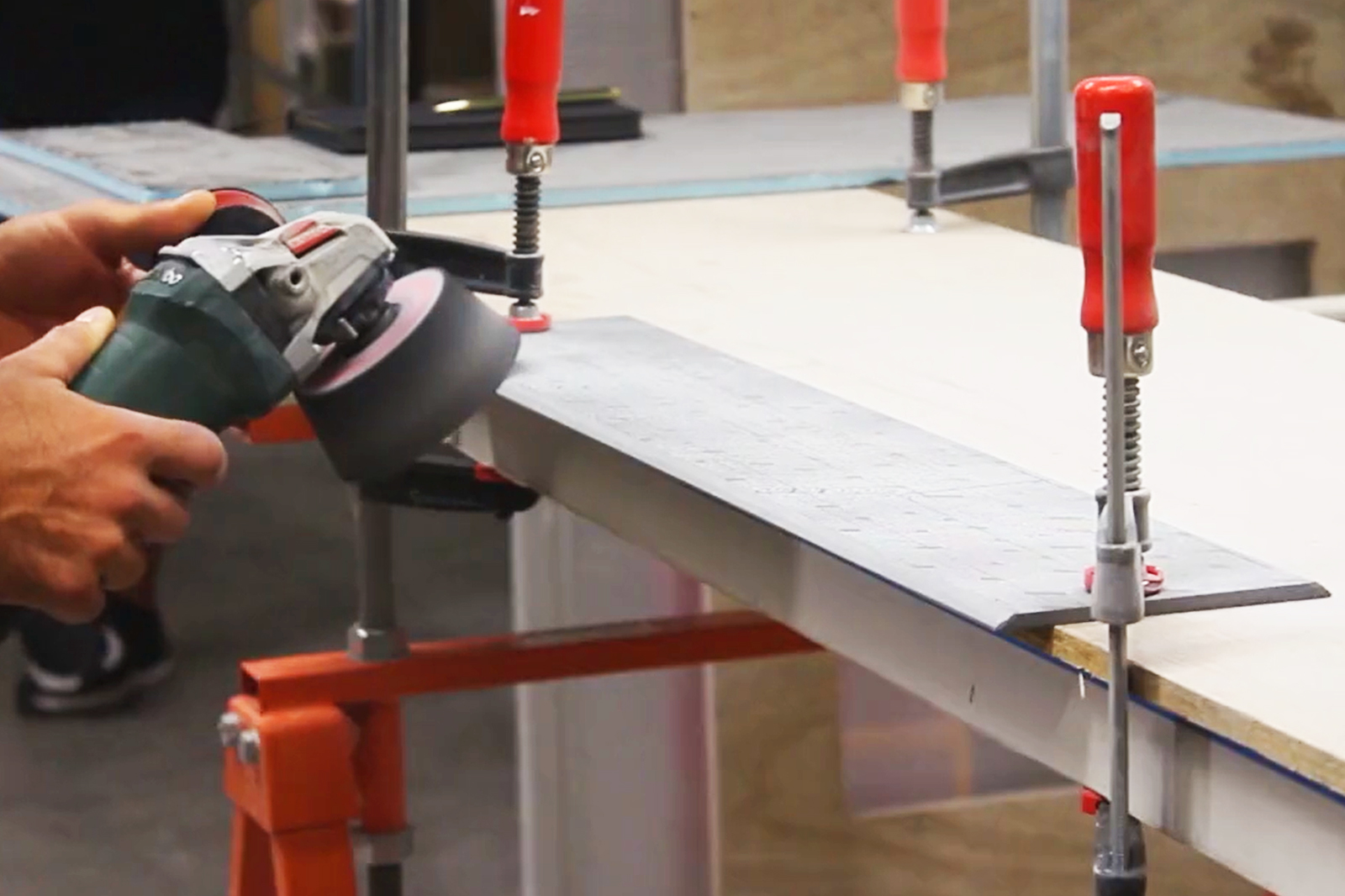

The updates to our procedure and protocol are many and have proven extremely effective. This includes respiratory protective equipment (RPE) training and how to wear and fit them properly. The correct methods to clean, maintain, and replace filters are all part of this practice. Another major safety initiative involves the tools used. We work with items that utilize water suppression as they’re far better at reducing dust levels than dry methods with local exhaust ventilation.

If there's no airborne RCS, there's no silicosis. Dry cutting, grinding or polishing stone generates high levels of dust containing RCS. These tasks require tools equipped with water suppression or built-in exhaust ventilation systems. It's best practice to minimize worker exposure with automated cutting equipment and water suppression. With an adequate number of water feeds directed at the material and/or tool to prevent dust during the process, the risk is greatly reduced.

In addition, there is exposure monitoring for fabricators which focus on the key areas required to prevent silicosis. In fact, part of the Health and Safety at Work Act 2015 (HSWA) requires the monitoring of workplace safety and the health of workers. This monitoring must be performed by a competent occupational hygienist. Mandatory online training has also been implemented to cover the core elements of the safety process. Workers must be trained and aware of the health hazards of respirable silica dust. This includes how to use and maintain the water-assisted equipment and extraction systems to prevent the release of dust.

Further Controls

Other effective steps include wetting slabs before cutting grinding or polishing to aid with dust suppression and capturing all generated water through curbing and channelling. Workers are also required to wash their hands and face thoroughly before eating, drinking, or leaving the workplace. Cleaning and housekeeping include no dry sweeping or compressed air to clean surfaces or clothing. Implementing daily and thorough housekeeping and cleaning procedures for water slurry and settled dust. Using low water pressure wet sweeping or with dry dust using H-class vacuum cleaner fitted with a HEPA filter to clean floors walls and other surfaces. Regularly clean vehicle track and high use areas and keep them wet during the day. Providing hoses for cleaning between tasks and placing wet slurry in a container, bag, or bin with a lid for disposal.

Managing Risk Properly

We are fully committed to a safe environment for all and continue to act in this pursuit. Improvements in risk management is an ongoing process. As we research to learn more about the disease and exposures in New Zealand, there will be continued health monitoring requirements. It should be noted that there are also other options coming onto the market with significantly lower silica content that would reduce the RCS exposure risk.

Health monitoring can detect lung problems early. The best health check currently available for engineered stone workers is the new accelerated silicosis assessment. This was made available in September 2020 for anyone who has worked with engineered stone for at least six months in the last 10 years. It starts with a subsidized visit to the GP, and subsequent tests and investigations are covered by ACC. Businesses are encouraged to cover GP visit costs and give workers paid time off for any tests or investigations that they may need.

In Closing

By managing the risks properly, engineered stone can be safely installed. The key component here is for companies to continue following the protocols detailed above. We are grateful for the science which alerted the industry to the need for change. With these guidelines in place, we’re confident that consumers can enjoy stone products in their homes without causing harm to those installing them.